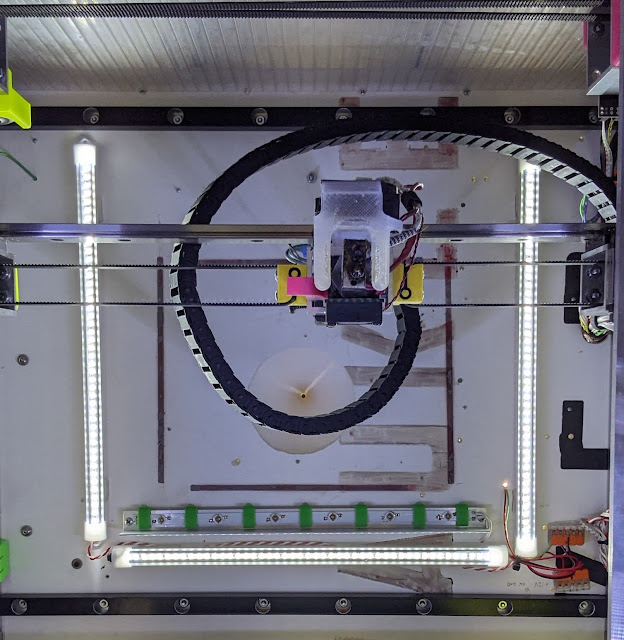

I found some 12V, 6000K LED bars at amazon and ordered them, pulled the old white LED strips off the ceiling, and installed the new LED bars. I used some Wago lever nuts to connect the bars together and to 12V.

|

| The new 12V LED bars came with mounting hardware. They are good for about 3W each. |

|

| The new LED bars installed in the printer. |

One thing I didn't like too much about the printer was the way I had to cut notches in the upper front cover to accommodate the XY stage belts because the motors are mounted outside the printer enclosure. I always thought it looked sort of ugly. I thought about it a little and realized I could just print some pieces to fit on the frame, then cut nice square notches in the front cover and it would probably look nicer, and might even seal a little better to keep the heat inside the enclosure.

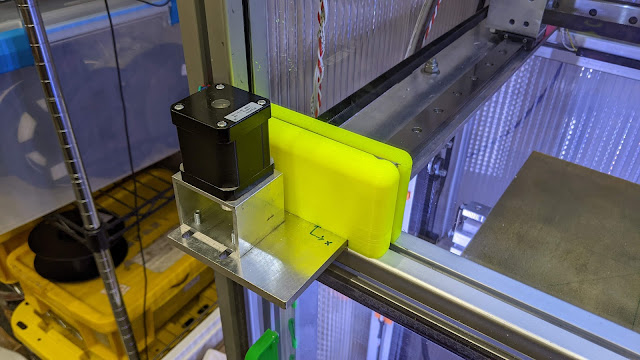

|

| Here's the B motor with notches cut in the front cover for the belt and the bolts that hold the XY stage together. |

I got to work in Fusion360 and came up with two parts to print that look a little neater. I thought about printing a single piece to fit across the width of the front panel, but realized that unless I printed it vertically, the bed wasn't big enough to make it as a single piece. So I split it into two pieces.

That's it. No big deal.