I wanted to play with my VDG a couple weeks ago and discovered that it was producing absolutely no sparks, even though the air in my house was so dry my skin was cracking. I set about troubleshooting...

First I tried wiping the tube down with alcohol to make sure it hadn't accumulated some sort of conductive dust (?). Nope, that wasn't it.

Then I tried swapping the fancy brushes I had pulled from a laser printer for the old standard aluminum tape with the edges clipped to make many sharp points. Nope. I put the fancy brushes back.

Then I checked the ground wire to see if the cats had chewed through it. They had definitely been working on it, but hadn't chewed all the way through it yet.

Finally I took the belt off and examined the pulleys. The top pulley, covered with Teflon tape, felt sort of rubbery, as if the thin layer of Teflon had worn through. The bottom roller, covered with aluminum tape, likewise felt sort of rubbery. Hmmm. Close examination of the belt found its surface getting sort of crumbly and sticky. Bingo! The failing belt had left residue on the Teflon and aluminum rollers so there wasn't any triboelectric effect working any more.

It makes sense, if you think about it- as the belt goes onto a roller it stretches to conform to the roller surface, and as it comes off the roller, it relaxes again. The belt is like a pencil eraser scrubbing on a piece of paper, leaving crumbs behind.

I replaced the Teflon and aluminum tapes on the top and bottom rollers, and stitched together a new belt from some fresh therapy-band material, put it all back together, and POW! The machine was throwing long, painful sparks into my hand again.

|

| Bottom roller covered with fresh aluminum tape, fresh belt, and fancy brush. |

|

| Top roller, fresh Teflon tape, fresh belt, and fancy brush. |

If you have a VDG and it mysteriously stops working, it may be time to replace the belt and clean or replace the coatings on the rollers.

One more thing- the rims of the two Ikea serving bowls used to make the spherical terminal at the top of the generator have no lips so it's almost impossible to stand one on the other, edge to edge, and have the top one stay in place. It's a two person job to hold the top bowl in place to tape the two together, but once taped, you can't access the inside of the sphere. That means you can't show disbelievers the inner workings of the generator. Who would believe that all it takes is a rubber band, a small motor, and a couple plastic rollers to generate >500 kV if they didn't see it with their own eyes?

I got some help from Jake (the knight who does battle with a giant Tesla Coil at the Milwaukee MakerFaire) at the Milwaukee Makerspace and we TIG welded three small stainless steel screws to the inside edge of the top bowl. After welding I cut the heads off the screws with bolt cutters and ground what was left down to nubs, just a few mm long. The screws rest just inside the rim of the bottom bowl and keep the top bowl in alignment, without tape.

|

| top bowl with three screws welded to inside rim. |

|

| One of the screws welded to the rim of the top bowl. |

Now when I run the generator, after a few seconds of operation I can draw 600+ mm long sparks to my arm. If I stay away from it and just let the VDG run, it fires sparks into the air with a menacing "SNAP" every few seconds!

|

| Look ma! No tape holding the bowls together! |

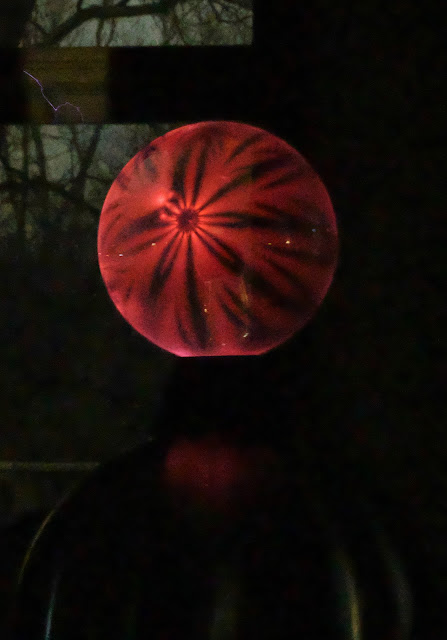

Here are a few fresh pictures of the generator doing what it does best:

Ahhh this is much more like it. Job well done.

ReplyDeleteI made a belt out of silicone rubber with a bottom roller of teflon and a top roller of nylon and I get zero charge. Any ideas?

ReplyDeleteI'm not sure where silicone rubber is on a triboelectric series, but it seems those materials should work. Maybe there's a problem with the brushes. Be sure to ground the brush on the lower roller.

DeleteOzone from the discharge at the brushes will degrade the latex belt and other parts. When I was a teen I used a glass tube from a fluorescent bulb. Cut the ends off and cleaned out the phosphor coating. Mercury was not a concern back then.

ReplyDeleteWhen I was a kid, my aunt had a hearing aid that used batteries that contained mercury. I used to get her old batteries and put them in a vise and squeeze the mercury out of them to play with it.

DeleteI have found that the VDG belts degrade and require periodic replacement, and that as they degrade, they leave tiny bits of rubber on the rollers which then interferes with developing a good charge. So if you build a VDG, plan on replacing the belt and cleaning off the rollers once in a while.

What is the belt made of

ReplyDeleteThere's link to the material immediately above the first photo up above. Theraband makes both latex and non latex bands. They don't say what the non latex bands are made of. If you are concerned about allergies, use a non latex band.

Delete